Tube hydroforming technology research and development

Honley car has extensive experience in the technical field of hydraulic pipe forming, the current understanding of the domestic tube hydroforming, punching, bending preformed related applications are still below 440MPa, no high-strength steel Forming analysis and related applications in hydraulic pressure.

The future development of 440 ~ 980MPa process technology of high-strength tube hydroforming, and for pre-high-strength steel forming, the elbow, hydraulic and other forming characteristics related research.

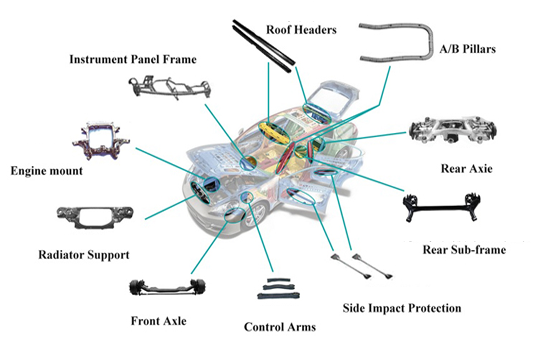

The status of the application of hydraulic fittings components of the vehicle, as shown below:

Solution Features

- High-strength steel bending technology.

- Integrated high-strength steel hydroforming technology to meet customer demand for the car parts.

- A full range of high-strength steel parts hydraulic punching technology, so that enterprises have more choices of different steel and automotive parts.

- Hydroformed high-strength steel spring verification analysis.

Process characteristics

- Tube Hydro-Forming,Abbreviation THF,Also known as Internal High Pressure Forming

- Application of high pressure fluid to make plastic forming technology of hollow pipe

- Typically pressures up 2,000Bar, under special circumstances even up 3,000 ~ 4,000Bar

- The main processes: (1) tube (2) bends and pre-press molding (3) Hydraulic rose shape.

- rends: in the high-strength steel hydroforming technology.